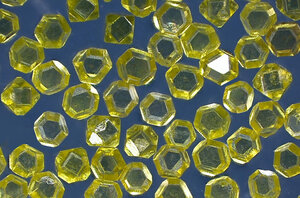

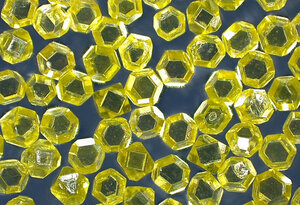

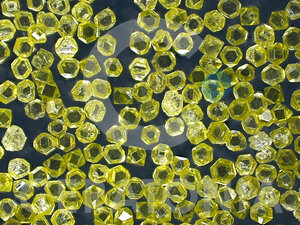

CERAGRIT - Saw grit synthetic

For sintering temperatures up to 1.000 ° C and higher

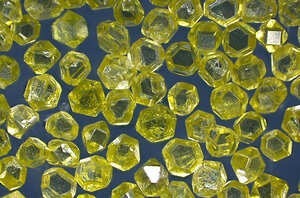

Our synthetic diamonds are of consistent quality, so that we can meet all the requirements of the tool application.

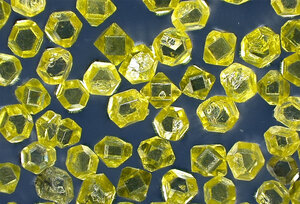

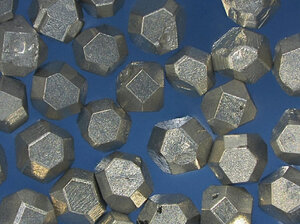

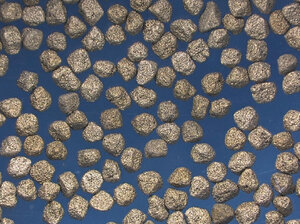

CNF 3090

- Crystals: Very regularly formed, hardly inclusions, no cube shapes; very heat resistant and of very high impact resistance

- Toughness: very high

- Application: sawing of hard concrete with or without reinforcement and a high rate of most abrasive aggregates. Asphalt, granite with large diameter blades, core drilling of reinforced hard concrete, wall sawing

Grit sizes | CNF 3100 | CNF 3090 | CNF 3080 | CNF 3070 | CNF 3060 | CNF 3050 | CNF 3040 | CNF 3030 | CNF 3010 | ||

| Mesh | FEPA | ||||||||||

| 16/18 | D 1181 | X | X | X | X | X | X | ||||

| 16/20 | D 1182 | X | X | X | X | X | X | ||||

| 18/20 | D 1001 | X | X | X | X | X | X | ||||

| 20/25 | D 851 | X | X | X | X | X | X | X | X | ||

| 20/30 | D 852 | X | X | X | X | X | X | X | X | ||

| 25/30 | D 711 | X | X | X | X | X | X | X | X | ||

| 30/35 | D 601 | X | X | X | X | X | X | X | X | X | X |

| 30/40 | D 602 | X | X | X | X | X | X | X | X | X | X |

| 35/40 | D 501 | X | X | X | X | X | X | X | X | X | X |

| 35/45 | - | X | X | X | X | X | X | X | X | X | X |

| 40/45 | D 426 | X | X | X | X | X | X | X | X | X | X |

| 40/50 | D 427 | X | X | X | X | X | X | X | X | X | X |

| 45/50 | D 356 | X | X | X | X | X | X | X | X | X | X |

| 45/60 | D 357 | X | X | X | X | X | X | X | X | X | |

| 50/60 | D 301 | X | X | X | X | X | X | X | X | X | |

| 60/70 | D 251 | X | X | X | X | X | X | X | X | X | |

| 60/80 | D 252 | X | X | X | X | X | X | X | X | X | |

| 70/80 | D 213 | X | X | X | X | X | X | X | X | X | |

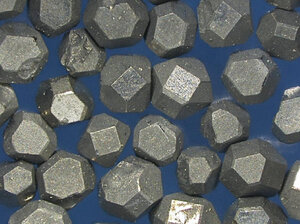

Coatings support the thermal conductivity, extend the life of the tools and improve the process properties of the workpiece.

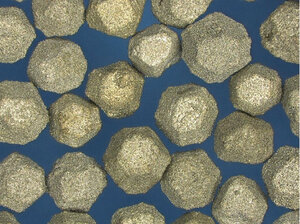

Ni

Nickel Ni 30 %, 50 %, 56 %

The surface of this kind of coating is smooth. The lifetime of the tools can be extended due to the extreme retention between the nickel layer and the surrounding bond. The coating can protect the diamond from erosion and at the same time expands the area of action of the diamond grit. This way the energy consumption is reduced and the cutting ability is increased.

CERADIA - Abrasive grit synthetic

| CNF | Abrasive grit for metal bond, available also coated | ||

| CNF-E | Abrasive grit for electroplating bond | ||

| CRG | Abrasive grit for resin bond |

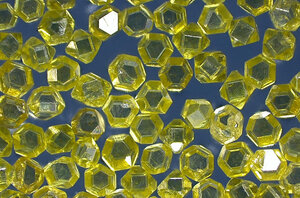

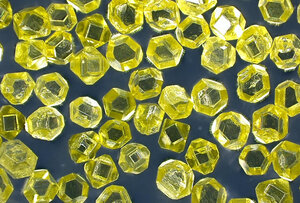

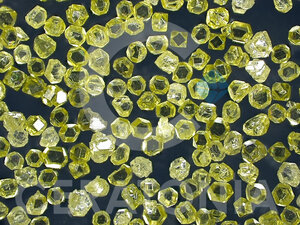

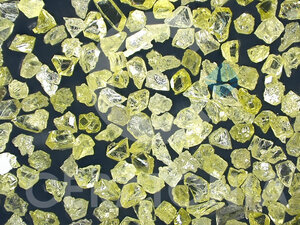

CERADIA CNF - Abrasive grit synthetic

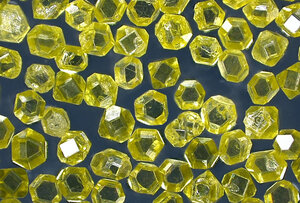

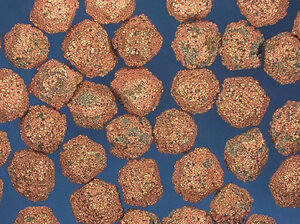

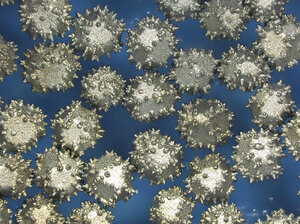

CNF 3080

High quality crystalline abrasive grit with a small amount of inclusions. The crystal shape is little more irregular and due to the inclusions less thermally resistant. Good strength. Suitable for glass processing, decor grinding, facet grinding and drilling of crystal glass, metal grinding. Used in metal bond applications.

Grit sizes | CNF 3100 | CNF 3090 | CNF 3080 | CNF 3070 | CNF 3060 | CNF 3050 | CNF 3040 | ||

| Mesh | FEPA | ||||||||

| 80/100 | D 181 | X | X | X | X | X | X | ||

| 100/120 | D 151 | X | X | X | X | X | X | X | |

| 120/140 | D 126 | X | X | X | X | X | X | X | |

| 140/170 | D 107 | X | X | X | X | X | X | X | |

| 170/200 | D 91 | X | X | X | X | X | X | X | |

| 200/230 | D 76 | X | X | X | X | X | X | ||

| 230/270 | D 64 | X | X | X | X | X | X | ||

| 270/325 | D 54 | X | X | X | X | X | X | ||

| 325/400 | D 46 | X | X | X | X | X | X | ||

Available grit coating

Coatings support the thermal conductivity, extend the life of the tools and improve the process properties of the workpiece.

Ni

Nickel Ni 30 %, 50 %, 56 %

The surface of this kind of coating is smooth. The lifetime of the tools can be extended due to the extreme retention between the nickel layer and the surrounding bond. The coating can protect the diamond from erosion and the same time expands the area of action of the diamond grit. This way the energy consumption is reduced and the cutting ability is increased.

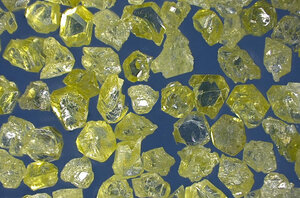

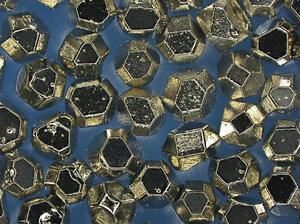

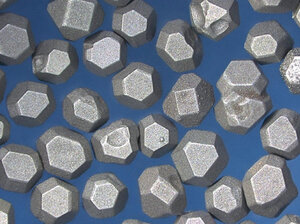

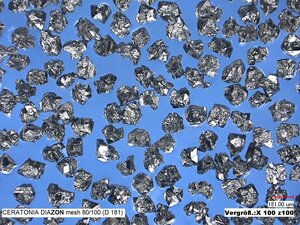

The innovative grit for applications that have previously used diamond or CBN.

The advantages of both materials combined in a single grit for better erosion performance with longer service lifes.

CERATONIA DIAZON has a multi-crystalline structure that retains a sharp cutting edge throughout the griding process and continuously genrats ew micro-cutting edges thanks to its permanent self-shrpening properties.

Normally, a monocrystalline diamond has a macro-crystalline structure and breaks up into large pieces. Therefore, the use is ideal for vitrified bonds, resin bonds and honing tools.

Grit Sizes | |

| FEPA | U.S. Standard Mesh |

| D 251 | 60/70 |

| D 231 | 70/80 |

| D 181 | 80/100 |

| D 151 | 100/120 |

| D 126 | 120/140 |

| D 107 | 140/170 |

| D 91 | 170/200 |

| D 76 | 200/230 |

| D 64 | 230/270 |

| D 54 | 270/325 |

| D 46 | 325/400 |

| D 35 | 400/500 |