CERABON CBN - Abrasive grit with high hardness

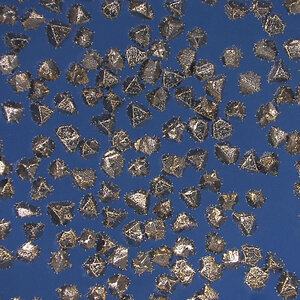

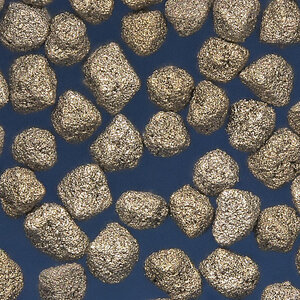

mono crystalline | poly crystalline | various coatings

The high hardness grade, highest temperature resistance and chemical stability when in contact with iron, make CERABON CBN the best abrasive grit for processing ferrous metals. Cubic boron nitride is, after natural diamond, the second hardest material. The synthesis from hexagonal boron nitride is similar to the fabrication of synthetic diamonds made of graphite.

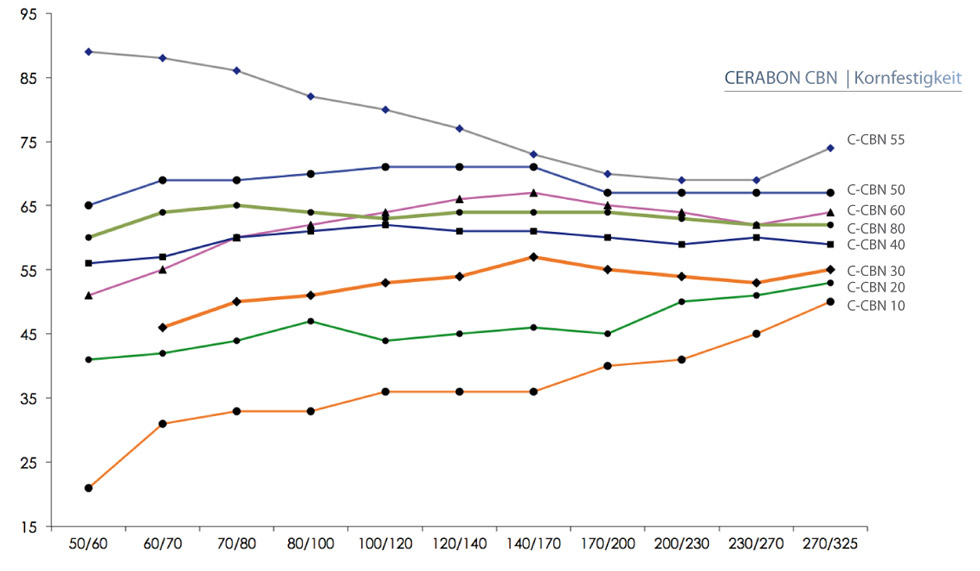

The most important advantages of CBN abrasive is its hardness, abrasion resistance, strength and resistance to thermal and chemical impact.

CERABON - Products

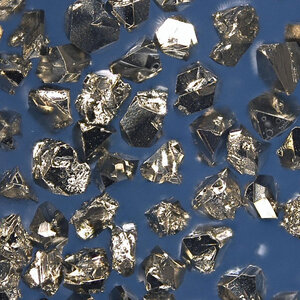

CBN 55

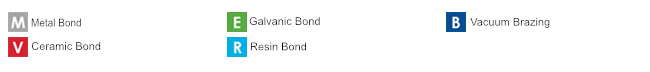

Extremely high fracture strength unmatched by any mono crystalline CBN grit. Grit shape, surface characteristics and an evenly distributed strength guarantee high abrasive capacities and excellent surface qualities, regardless of the grit size. The grit is mainly used in metal and electroplated tools as well as vacuum brazed bond systems.

| Grit sizes | CBN 10 | CBN 20 | CBN 30 | CBN 40 | CBN 50 | CBN 55 | CBN 60 | CBN 80 | |

| Mesh | FEPA | ||||||||

| 30/35 | B 601 | X | X | X | X | ||||

| 30/40 | B 602 | X | X | X | X | ||||

| 35/40 | B 501 | X | X | X | X | ||||

| 35/45 | --- | X | X | X | X | ||||

| 40/45 | B 426 | X | X | X | X | ||||

| 40/50 | B 427 | X | X | X | X | ||||

| 45/50 | B 356 | X | X | X | X | ||||

| 45/60 | B 357 | X | X | X | X | ||||

| 50/60 | B 301 | X | X | X | X | X | X | X | |

| 60/70 | B 251 | X | X | X | X | X | X | X | X |

| 60/80 | B 252 | X | X | X | X | X | X | X | X |

| 70/80 | B 213 | X | X | X | X | X | X | X | X |

| 80/100 | B 181 | X | X | X | X | X | X | X | X |

| 100/120 | B 151 | X | X | X | X | X | X | X | X |

| 120/140 | B 126 | X | X | X | X | X | X | X | X |

| 140/170 | B 107 | X | X | X | X | X | X | X | X |

| 170/200 | B 91 | X | X | X | X | X | X | X | X |

| 200/230 | B 76 | X | X | X | X | X | X | X | X |

| 230/270 | B 64 | X | X | X | X | X | X | X | X |

| 270/325 | B 54 | X | X | X | X | X | X | X | X |

| 325/400 | B 46 | X | X | X | X | X | X | X | X |

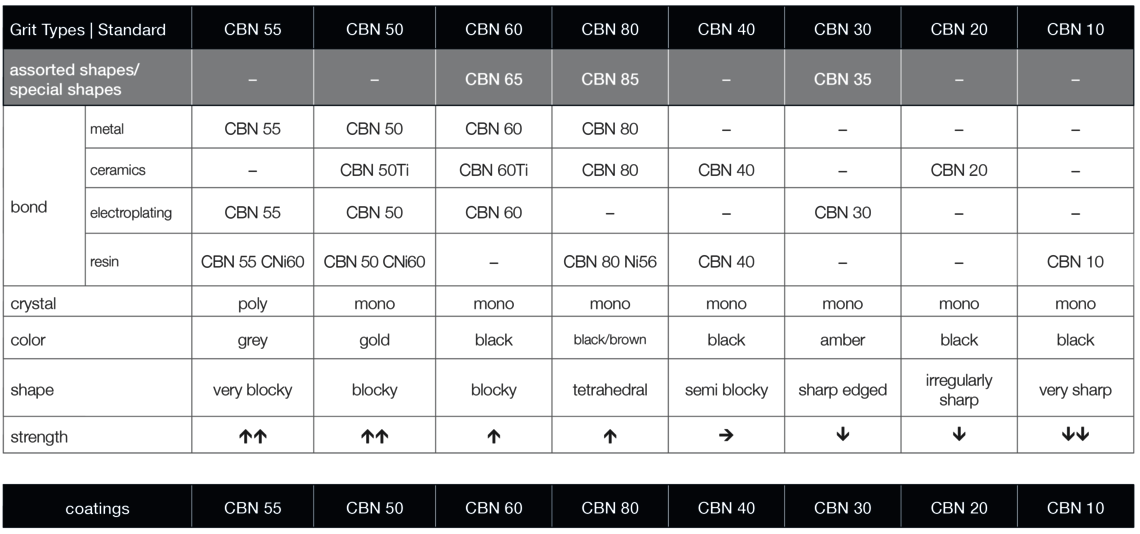

The most important advantages of CBN abrasives is its hardness, abrasion resistance, strength and resistance to thermal and chemical impact. At the same time CERABON CBN grit provides sharp cutting edges and in comparison outperforms conventional abrasives like SiC and Al2O3 in every respect. Highest temperature resistance and the chemical characteristic of not releasing carbon to steel, in elevated temperatures, makes CBN the most suitable abrasive for processing ferrous and hardened metals. Normally diamond abrasive can not be used in these kinds of applications. Different types of CBN with different grades in hardness provide a wide choice for applications with various load impacts and bonds.

CBN coated (Ti, Ni, CNi)

Coatings with Titan (Ti), Nickel (Ni) and chemical Nickel (CNi) are available for all types.