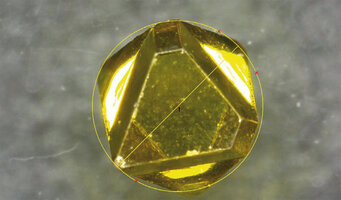

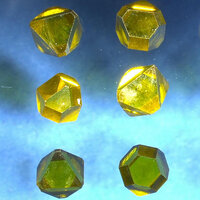

With larger sizes or special crystal orientations, the shape may be change to a rhombic-dodecahedron shape or simply plate like crystals. In a standard controlled process, the output of HPHT (High Pressure-High Temperature) synthesis are mainly topped octahedron shapes.

During the growing cycle, the diamond crystals develop a light yellow color. This in no way affects their performance. The color is caused by nitrogen atoms trapped in the crystal’s lattice during synthesis.

The required dimensions always depend on the customer’s application. In general CERATONIA delivers diamonds with diameters up to 4 mm. The weight is shown in carats. One carat is 0,2 grams.

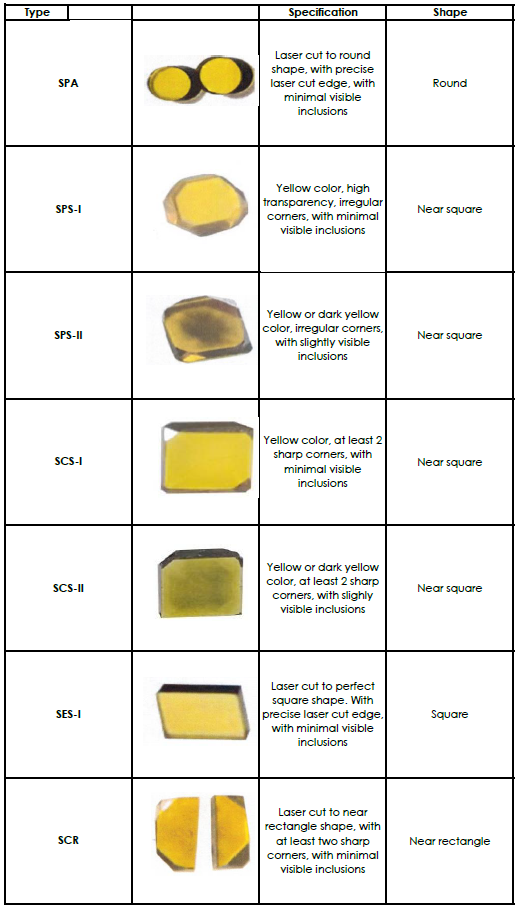

Due to the specifics of the growth process, the character of each diamond will vary slightly. As with mined diamonds, the rough synthetic stones are carefully sorted into various qualities and grades. Each grade reflects, for example, the presence of internal inclusions or irregular shape forms. CERATONIA has 5 quality grades available.

The HPHT hi-tech process and sorting ensures not only a consistent high quality of grown diamonds, but also repeatability of chemical, physical and thermal characteristics.

| Property | Value |

|---|---|

| Hardness | 10,000 kg/mm2 |

| Density | 3.51 g/cm3 |

| Young´s modulus | 1.22 Gpa |

| Index of refraction at 650 nm | 2.41 |

| Thermal conductivity | 1200 W/mK |

| Optical transmissivity at 650 nm | 65% |

| Wear resistance | up to 15% higher than natural diamond |

| Complete impurity absorption | 450-500 nm |