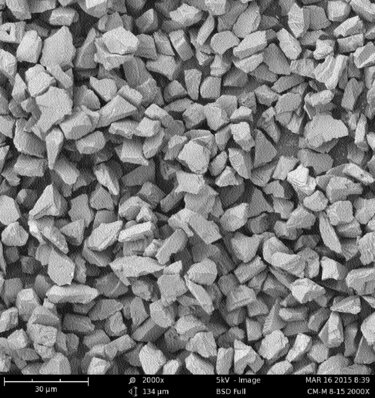

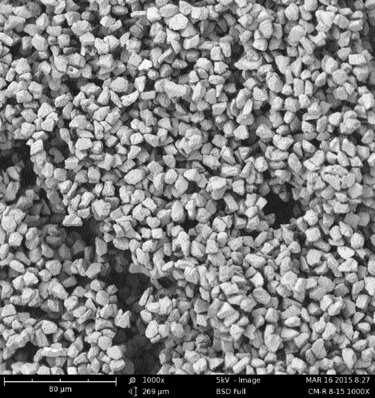

Synthetic RESIN: CM–R (Resinbond)

The variety of cutting edges which CM-R offers, makes the crystals extremely cut-off. Mosaic - like structures and the irregular, less-blocky particle shape create the optimal properties for gentle polishing and lapping with lower cutting forces compared to CM-M or CM-MB. CM-R allows fast cutting without crystal fracture and is aimed at smooth surfaces with slightly reduced removal capacity compared to CM-M.