CERAMIKRON Diamond- und CBN - Micron powder in high quality

CERATONIA has been supplying diamond raw materials to the tool industry since 1996 and has made a name for quality and service. We supply high-quality natural and synthetic diamond grit as well as powders with a wide selection for lapping, honing, grinding, polishing and machining with polycrystalline raw plates (CERATON CVD and CERADITE PKD).

Our products are carefully selected and subjected to regular quality checks in order to ensure the delivery of the same quality. SERVICE is important in our house. We look after you individually and adapt to your needs.

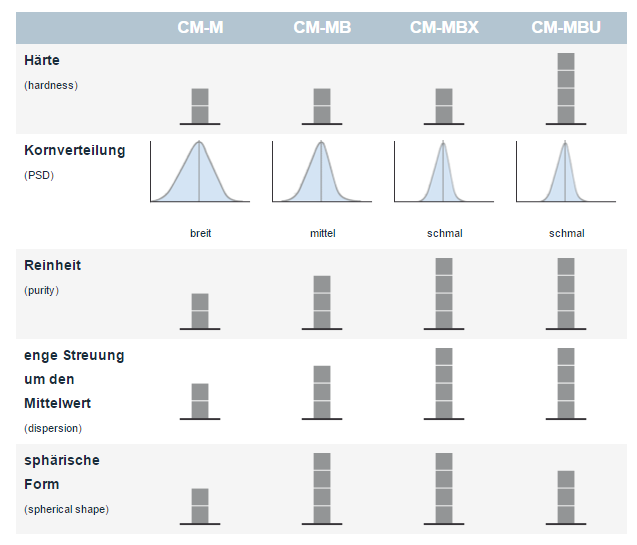

CERAMIKRON diamond micron powder differs by different strengths, grit forms and inclusion levels of metals and catalysts. The structure of the column planes in the crystals determines the pressure at which a grain breaks. If the grain is bound in the tool, the fracture of the grain results in a continuous re-sharpening effect.

CERAMIKRON The product family

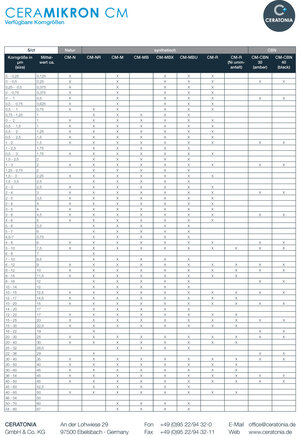

For different requirements, depending on the application as bound grain or in suspensions, we offer you 10 grain qualities to choose from. The individual products differ according to shape, strength, inclusions as well as the grain distribution within one size.

| Produktnames | Overview |

|---|---|

| CM-N | Natural diamond, gained from the fragments from processing natural diamond grain. |

| CM-NR | Synthetic, fractured, very sharp-edged diamond grain, similar to natural diamond. NR stands for Natural Replacement |

| CM-M Family | Synthetic diamond micron grain (M stands for the preferred bond: metal bond - the grain has to be blocky for that purpose) |

| CM-R | Synthetic (R stands for resin bond), brittle, low hardness, sharp-edged shape |

| CM-DD | Polycrystalline diamond grain (DD: stands for detonation diamond) |

| CM-CBN 30 | CBN micron grain, gained from the synthesis of amber colored CBN 30 |

| CM-CBN 40 | CBN micron grain, gained from the synthesis of black colored CBN 40 |

| CM-CBN 80 | brown, black micro monocrystalline powder with high hardness, suitable for demanding applications in vitrified or metal bond of CBN 80 |

Grain sizes and qualities:

The variety of cutting edges which CM-R offers, makes the crystals extremely cut-off. Mosaic - like structures and the irregular, less-blocky particle shape create the optimal properties for gentle polishing and lapping with lower cutting forces compared to CM-M or CM-MB. CM-R allows fast cutting without crystal fracture and is aimed at smooth surfaces with slightly reduced removal capacity compared to CM-M.

Application focus = synthetic resin bond