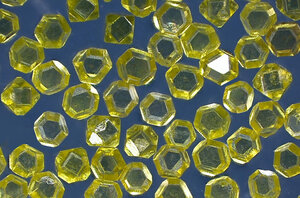

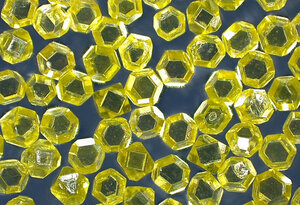

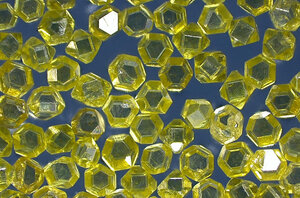

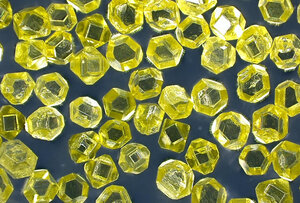

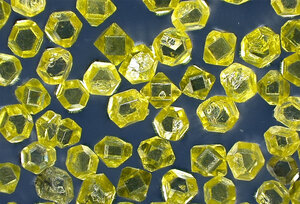

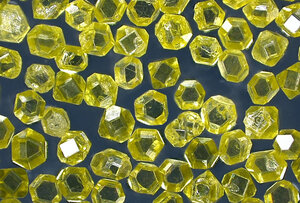

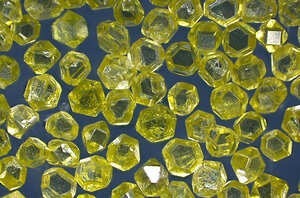

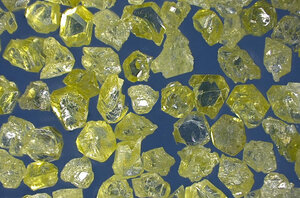

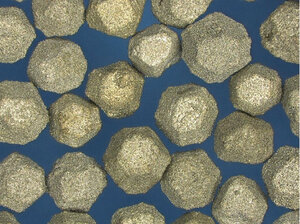

Saw grit synthetic

CERAGRIT - Saw grit synthetic

For sintering temperatures up to 1,000 ° C and higher

Diamonds are generally differentiated into 2 categories: natural and synthetic. The natural diamond is the hardest known naturally occurring mineral. Both types are used as superabrasive and cutting material in the respective industries.

Since it is a material with the largest effective heat conductivity, it is also used in other sectors e.g. in the electronics industry as a heat sink or as a frequency wave filter in the communications industry.

We can meet all the requirements of the tool application, since our CERAGRIT saw grit synthetic is of consistent quality.

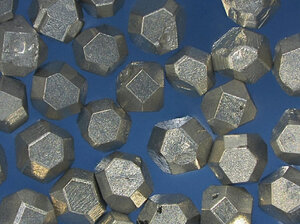

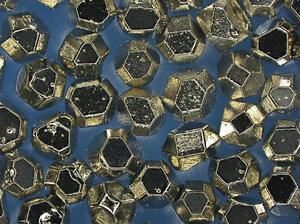

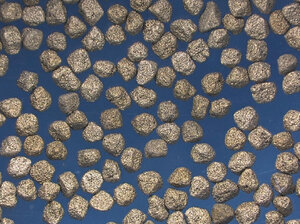

CNF 3090

- These crystals are very regularly formed with hardly inclusions and no cube shapes; the heat and impact resistance is very high.

- Toughness: very high

- Application: Asphalt, granite with large diameter blades, core drilling of reinforced hard concrete, wall sawing. Sawing of hard concrete with or without reinforcement and a high rate of most abrasive aggregates.

Grid sizes | CNF 3100 | CNF 3090 | CNF 3080 | CNF 3070 | CNF 3060 | CNF 3050 | CNF 3040 | CNF 3030 | CNF 3010 | ||

| Mesh | FEPA | ||||||||||

| 16/18 | D 1181 | X | X | X | X | X | X | ||||

| 16/20 | D 1182 | X | X | X | X | X | X | ||||

| 18/20 | D 1001 | X | X | X | X | X | X | ||||

| 20/25 | D 851 | X | X | X | X | X | X | X | X | ||

| 20/30 | D 852 | X | X | X | X | X | X | X | X | ||

| 25/30 | D 711 | X | X | X | X | X | X | X | X | ||

| 30/35 | D 601 | X | X | X | X | X | X | X | X | X | X |

| 30/40 | D 602 | X | X | X | X | X | X | X | X | X | X |

| 35/40 | D 501 | X | X | X | X | X | X | X | X | X | X |

| 35/45 | - | X | X | X | X | X | X | X | X | X | X |

| 40/45 | D 426 | X | X | X | X | X | X | X | X | X | X |

| 40/50 | D 427 | X | X | X | X | X | X | X | X | X | X |

| 45/50 | D 356 | X | X | X | X | X | X | X | X | X | X |

| 45/60 | D 357 | X | X | X | X | X | X | X | X | X | |

| 50/60 | D 301 | X | X | X | X | X | X | X | X | X | |

| 60/70 | D 251 | X | X | X | X | X | X | X | X | X | |

| 60/80 | D 252 | X | X | X | X | X | X | X | X | X | |

| 70/80 | D 213 | X | X | X | X | X | X | X | X | X | |

Coating types with diamond grain

Depending on the type of coating, it supports the holding forces between the grain and the bond, and / or the thermal conductivity and the reaction with the metal bond. In case of the right combination with the bond, the service life of the tools can be extended or the process properties can be optimized.

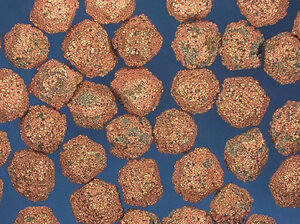

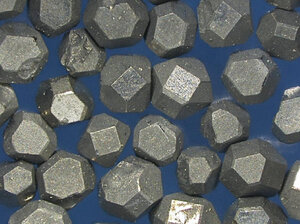

Nickel

Nickel Ni 30 %, 50 %, 56 %

Due to the extreme retention between the nickel layer and the surrounding bond, the lifetime of the tools can be extended. The coating can protect the diamond from erosion and at the same time expands the area of action of the diamond grit. This way the energy consumption is reduced and the cutting ability is increased. The surface of this kind of coating is smooth.