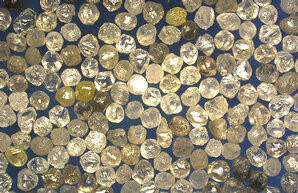

Type CN-P

Same blocky and sharp crystals for general application purpose including brick stone materials. Most suitable for cutting and drilling of asphalt and concrete. For same purpose it is used in construction (wall drilling) and marble industry in metal bond tools.

CN-P might include some light yellow coloured particles (3%) due to the natural isolated nitrogen inclusions.

Available sizes are from 16/18 mesh (D 1181) down to 325/400 (D 46).

Type CN-R50

This more friable version with an open structure is chemically processed (e.g. 50%) to remove its exposed tips and to make it more stable and more suitable for so called edge stabilizers and wear protection areas.

Available grid sizes 20/25 to 80/100 mesh or D 851 to D 181.

Type CN-WS

Showing first class blocky shaped crystals it is successfully used in rotating dressing tools.

Most common are sizes range from 20/25 mesh (D 851) to 40/50 mesh (D 427).

Type CN-NCW

Whole stones. First class blocky shaped crystals, generally used for dressing tools.

Available sizes are from 20/50 mesh to 40/50 or D 851 to D 427.

Longs

Suitable for standing and rotating dressing tools/tiles.

These longitudinal manually assorted shapes are handled in “stones per carat” i.e. called SPC. Manually set in row formation in free standing dressers they are used along the radius left/right in rotating dressing tools.

Commonly used sizes are 5, 10, 20, 30, 40, 50 and 60 SPC. (Stones per Carat)

Further sizes on request.

NATGRIT Natural Diamond

For dressing and grinding tools

Still natural diamond keeps its constant position in dressing and grinding applications because of its unique cristallographic structure and the resulting required low grinding forces.

Thermal stability

Competing against synthetic the NATGRIT natural diamond grit withstands much higher temperatures without the protection of any coating. Too, the crystals are of a higher “sharpness” and consequently more free cutting than synthetic. The higher thermal stability results from the general smaller amount of inclusions given by nature. This allows temperatures of more than 1.000° Celsius during tool production or under application without reducing the impact resistance.

Special natural grits of CERATONIA

To achieve tighter tolerance values in grinding results, we can offer the standard size range in so-called half sizes or even special sievings respectively. Upon customer’s special request individual sizes might receive a multiple number of sievings to get an optimum of a regular shape and size.